Our Specialties

Featured Product

-

DA 99

Heavy-duty servo actuator for spot welding and other industrial applicationsThe DA 99 series Roller Screw Servo Actuator is a time-proven solution for welding guns. The powerful 10-pole synchronous motor and in-house designs provide high performance and protection against water and welding sludge.

Join Our Team

-

FIELD SERVICES

-

QUALITY & HSE

-

ENGINEERING

-

CORPORATE BUSINESS

-

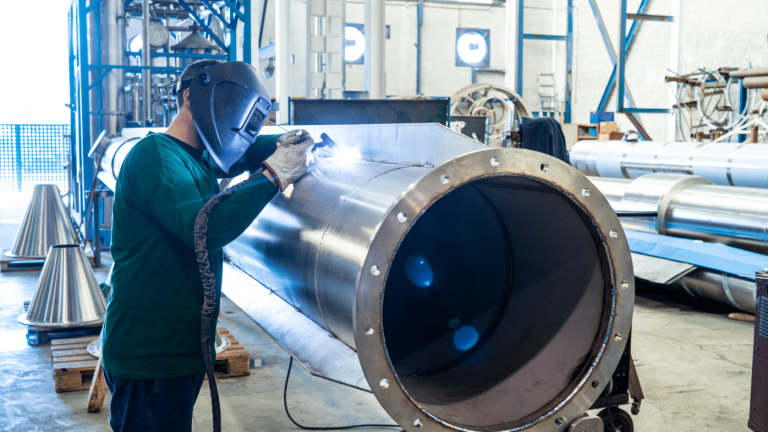

MANUFACTURING & PRODUCTION

-

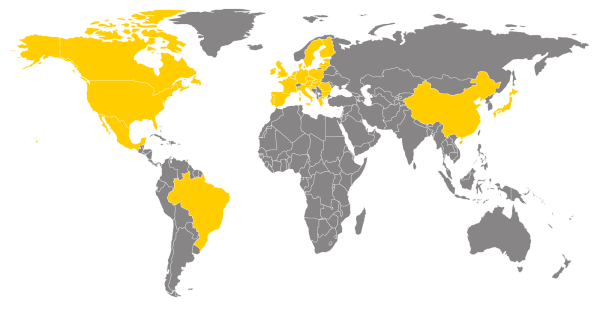

Principle Markets

Established

1990

Quality Management System

ISO 9001:2015

Let's Work Together

-