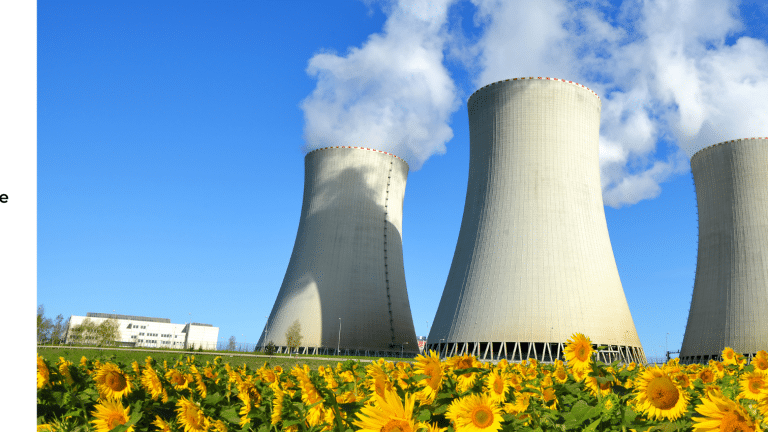

Diakont’s innovative refueling machines increase safety and performance of nuclear power plant operations. Since 2002, Diakont successfully delivered 35 upgraded refueling machine systems to nuclear power plants worldwide. The upgraded systems incorporate various automated features to handle simultaneous movements for reduced reloading time.

Challenge

- Reduce time on standard refueling operations during nuclear outages while increasing safety and performance.

Solution

- Implement Diakont’s modernized FHMs and advanced IMSS safety system with operational objectives that include:

- Safety assurance when performing all nuclear fuel transportation

- Digital control system upgrades to increase fuel movement efficiency

- Obsolete components replaced

- Extended operating life

Results

- Since 2002, Diakont has successfully delivered 35 upgraded refueling machine systems to nuclear power plants worldwide.

- This innovative refueling machine saves nuclear power plants 95 hours on average per outage during refueling operations

- An overall operational ease with reduced personnel dosage rate, reduced liquid radioactive waste, and a decreased need for clear borated water.

Optimized Structure Weight

Diakont’s bridge and trolley are optimized by weight to withstand extreme seismic effects. Diakont achieved a reduced weight by introducing several modern features. Separate drive trains, bridge seismic locks, and dedicated mast drives greatly reduces the weight by excluding the need for a comb rail and a number of kinetic train elements.

Seismic Locks and Guide Rollers

Diakont’s earthquake resistant fuel handling machines (FHMs) are capable of handling seismic category I situations and incorporate a 7-point safe earthquake shutdown system. During seismic influence, the seismic lock systems clamp down on the rail head to hold the fuel transfer machine still. A gapless contact is maintained with the bridge guide rollers to prevent the bridge position from skewing and increases positioning accuracy at specified coordinates.

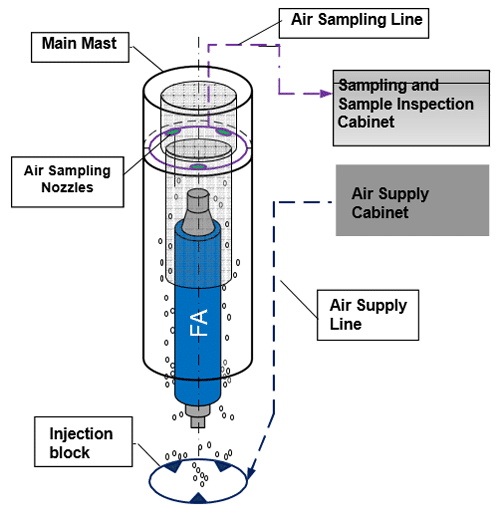

High-Efficiency In-Mast Fuel Sipping System

Diakont’s In-Mast Sipping System (IMSS) is a proven process for identifying leaking fuel assemblies. Since 2004, Diakont successfully delivered 31 in-mast sipping systems to nuclear power plants worldwide. The system vacuums, or sips, gas from the around the fuel assemblies, whereby the presence of xenon and/or krypton is used to indicate leaking fuel. Diakont’s IMSS inspects 100% of fuel assemblies and guarantees detection of fuel assemblies with leaking rods. Using the IMSS greatly increases fuel operational efficiency and decreases the refueling time by an average of 4-5 days per reactor.

The IMSS operates by delivering compressed air under the liner of each fuel assembly. A gas sample is taken from the inner cavity of the FHM above the water level and is measured with a beta-activity meter.

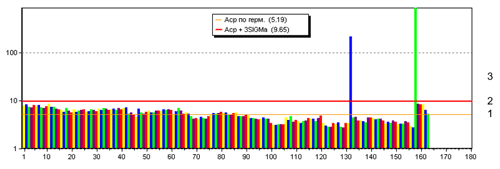

The following chart illustrates the beta-activity from a recent fuel assembly inspection using Diakont’s IMSS. Fuel assemblies 132 and 158 demonstrated beta-activity beyond the operational threshold and were removed.

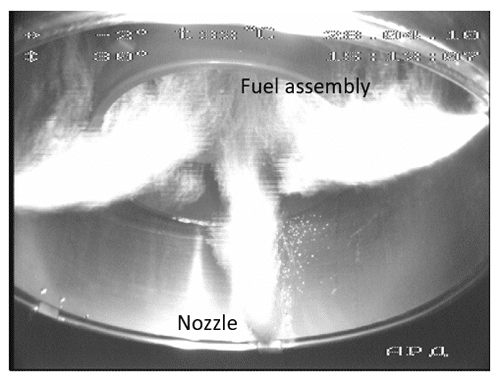

Monitoring Fuel Handling Operations

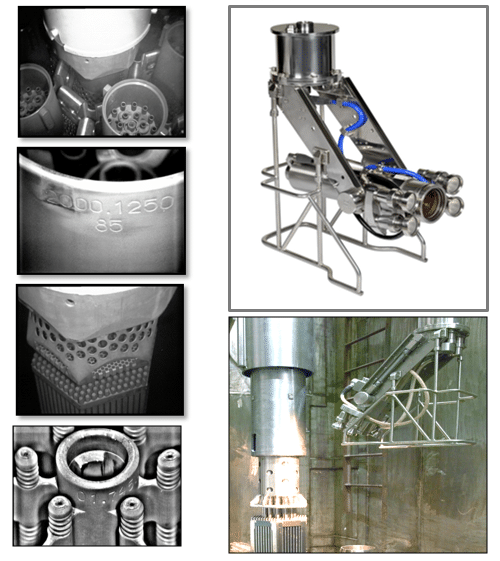

Diakont’s FHMs use high radiation video cameras integrated on pan & tilt units to provide comprehensive monitoring of all fuel handling operations. The system is capable of 6x zoom and has built-in underwater illuminators. Screenshots illustrating the system’s image clarity in high-radiation environments are shown below.

Refueling Results from Diakont’s FHMs with IMSS

Diakont’s modernized FHMs and advanced IMSS safety systems greatly reduce refueling time by automated features to handle simultaneous movements. The following table illustrates the time saving results achieved from incorporating Diakont’s FHMs.

| Refueling Operations | Refueling Performance of Legacy FHM | Refueling Performance of Diakont’s FHM |

| Reloading of one FA from reactor to spent fuel pool | 40 min | 20 min |

| Reloading of one FA from spent fuel pool to reactor | 38 min | 23 min |

| Total reactor core unloading (163 Fas) | 108 hours | 55 hours |

| Total reactor core loading time (163 FAs) | 104 hours | 62 hours |

| Refueling time saving per 1 outage: | 95 HOURS | |

Performance Results from Legacy FHMs vs Diakont FHMs

Using Diakont’s modern FHMs and IMSS, nuclear power plants are able to save an average of 95 hours on standard refueling operations per outage. Further, plant operators that invested in Diakont IMSS reduced personnel dose uptake, reduced liquid radioactive waste, decreased the need for clear borated water, and increased ease of operation.