Diakont was commissioned to assess the integrity of a major North American natural gas pipeline, which was partially buried under an urban area. The company used a reduced size robotic crawler to successfully navigate a 10 in. pipe. The size of this pipe has previously been a limitation, making it ‘unpiggable’ using other inline inspection (ILI) methods.

Challenge

- Assess the integrity of a major North American natural gas pipeline partially buried under an urban area. Given the location of the pipe, the low flow, narrow10-in internal diameter (ID),and pipeline characteristics (e.g., tight bends, plug valves) it had never been inspected and was unsuitable for traditional smart-pigging.

Solution

- Implement Diakont’s Sprinter tool created for challenging pipeline geometrics.It’s ability to navigate across horizontal surfaces and extend to the tracks of the pipe wall for stabilization, made it ideal for this job.

Results

- The inspection went smoothly and was completed within five working days–one less than predicted. The HCA pipe was in excellent condition with only a few minor flaws, allowing the pipe return to service promptly.

Narrow Pipe ID Creates Inspection Hurdle For HCA Pipeline

Designated as a high consequence area (HCA) due to being located in a densely-populated urban area, this section of pipeline had never been inspected; low flow, its narrow 10-in. internal diameter (ID), and pipeline characteristics (e.g., tight bends, plug valves) made it unsuitable for traditional smart-pigging. However, United States federal Pipeline and Hazardous Materials Safety Administration (PHMSA) regulations require specific integrity management programs in HCAs. The piping’s inspection challenges could have forced the pipeline operator to replace the entire quarter-mile length of pipe if they could not inspect the line on schedule. The technology gap between inspection requirements and available tooling forced the industry work with pipeline service vendors to develop a solution.

A Reduced-Size, Self-Propelled Solution

The HCA consists of 1325 feet of partially-buried line located near a library, a school, and private homes. Low flow, pipeline geometry, and a lack of sufficient access points prevented the use and retrieval of a free-flowing smart pig. For these reasons, an ILI solution was deemed necessary, but most existing self-propelled ILI solutions readily available on the market were too large to navigate the piping’s narrow ID. The operator determined that a smaller form-factor inspection crawler solution was needed to navigate the piping’s challenging geometry (including vertical sections and mitered bends) as well as to allow entry and retrieval from a single access point without the large footprint of a pig launcher/receiver.

Faced with these inspection challenges, the pipeline operator turned to pioneering engineering firm Diakont Advanced Technologies for a solution. The operator selected Diakont’s Sprinter robotic crawler tool for the inspection because of its ability to negotiate unpiggable pipeline geometries with IDs as small as 8 inches. The Sprinter accommodates small IDs by arranging the robotic crawler track modules, control electronics, and NDE sensor suite modules into a linear assembly. The robotic modules attach together via rugged flexible connections, giving the Sprinter remarkable maneuverability. The Sprinter inspection system is mobilized on-site in separate sections and assembled near the pipe access point to reduce the space required for the inspection crew and the impact to the pipeline operator.

Diakont’s Sprinter tool traverses challenging pipeline geometries using a ruggedized multiple-track system for navigation across horizontal surfaces, and the tool can extend the tracks to the pipe wall for stabilization. This arrangement provides the necessary traction to hold the tool rigidly in place while inspecting difficult-to-access pipeline applications where conventional ILI tools may not be feasible, including inclines and vertical sections. This Sprinter system moves at a deliberate pace to provide accurate mapping of anomaly locations within the pipeline. Self-propelled and bidirectional, the Sprinter can also be deployed and retrieved from a single access point, which was another key feature in its selection for this inspection.

Diakont’s Sprinter tool is equipped with an advanced non-destructive examination (NDE) sensor suite to provide comprehensive assessments of pipe wall conditions:

- Diakont’s patented ultrasonic testing (UT) electromagnetic acoustic transducer (EMAT) module measures pipeline wall thickness

- High-definition cameras allow technicians to gather photographs and video of the appearance of the pipeline’s interior

- All sensor data feeds back to the inspection technicians in real time via an umbilical cable to permit same-day assessment results

Unlike conventional UT instruments that employ contact methods, the EMAT instrument does not require any liquid couplant between the transducers and pipe wall to transmit ultrasonic signals. This non-contact method is ideal for gas pipeline inspections, where liquid within lines is unacceptable.

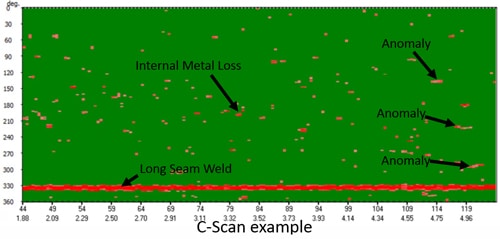

Diakont’s EMAT technology is capable of inducing the eddy current at multiple angles depending on the goals of the inspection. Direct-beam EMAT coils induce ultrasonic waves into the pipe wall at a 0° (radial) angle to detect pitting corrosion and determine remaining wall thickness. Angle-beam EMAT induces ultrasonic waves at angles inclined to the pipe’s ID surface to scan for pitting corrosion below the direct-beam threshold as well as cracks and SCC.

The EMAT transducers rotate circumferentially throughout the inspection to cover the entire pipe wall. Inspection technicians set reporting thresholds for identifying corrosion or cracks to accommodate each customer. The EMAT sensor readings provide measurement threshold accuracy of ± 0.01 in.

This methodology supplies structural integrity personnel with crucial information required for planning repairs. All pipe wall assessment data is also stored digitally to provide comprehensive data for monitoring corrosive areas. This baseline assessment information helps pipeline operators manage their assets more effectively through re-inspection and future capital planning.

In-Line Inspection

The operator excavated two access points for the inspection to permit crawler tool entry. Diakont mobilized an inspection team to operate the tool and monitor data. The team loaded the crawler into the pipe via removed pipe spools and navigated the inspection area while taking video of the interior and surveying pipe elements. Technicians then returned the crawler to the launch point and began a direct-beam EMAT inspection in automatic scan mode.

After completing the automatic scan, inspection technicians manually drove the robotic crawlers to each indication of a potential defect for detailed characterization. Throughout the inspection, the technicians reviewed the data in real time, monitored tool operation via telemetry, and recorded precise pipeline geometric data, which was incorporated into a pipe tally in the inspection report.

Inspection Results

The inspection went smoothly and was completed over a period of five working days—one day less than originally projected. The integrity assessment showed the HCA pipe to be in excellent condition, with only a few minor flaws. Having validated the integrity of the pipeline, the pipeline operator was able to return it to service promptly.